Roastery Workflow Design: How to Roast Coffee Beans Efficiently & Safely

Roast Radar | Issue #3

Picture this: It’s 6 AM, and your day starts with green coffee beans stacked by the door, a grinder waiting to roar, and wholesale coffee orders piling up. You're darting between green coffee bags scattered across the floor, fumbling for labels, stepping around equipment and electrical wires that are blocking your path, and realizing you've already walked the length of your roastery twelve times just to complete one batch. Now imagine the alternative: a space where every movement has purpose, every tool has its place, and your morning flow feels like a well-choreographed dance rather than a frantic scramble.

Creating an efficient and safe workflow, designed for repeatable tasks, is gold. It's the difference between a roastery that scales smoothly and one that breaks your back, and your spirit, every single day.

The success of a microroastery isn't just about great coffee, it's about eliminating friction in how that coffee moves through your space. When your workflow fights against you, you waste time, energy, and money. When it works with you, you can focus on what matters: roasting exceptional coffee and growing your business.

This guide is for microroastery owners who are serious about leveling up their operational design to match their ambition. Whether you're planning your first space or redesigning an existing one, these principles will help you create a foundation for sustainable growth.

Step 1: Start with Your Constraints

Before you dream about the perfect workflow, get honest about what you're working with. Your constraints aren't limitations, they're the framework that makes creative solutions possible.

Space considerations drive everything else. How much square footage do you have? What's the ceiling height for ventilation and storage? Do you have loading dock access, or are deliveries coming through a standard door? Where can you access walls for electrical and ventilation hookups? These factors determine not just where things go, but how they flow together.

Team size shapes your entire approach. A solo operator needs everything within arm's reach and sightlines to monitor multiple processes. A small crew needs clearly defined zones that don't create bottlenecks or safety hazards when multiple people are working.

Volume and frequency questions reveal your true needs. How many pounds are you roasting per week? How often do green coffee deliveries arrive? What's your typical order fulfillment schedule? A roastery handling 50 pounds a week has very different storage and workflow needs than one moving 500 pounds.

Budget reality keeps your plans grounded. What can you build or modify yourself? What requires professional installation? Sometimes the best solution is a $50 rolling cart, not a $5,000 custom fixture. Start with function, then upgrade when revenue supports it.

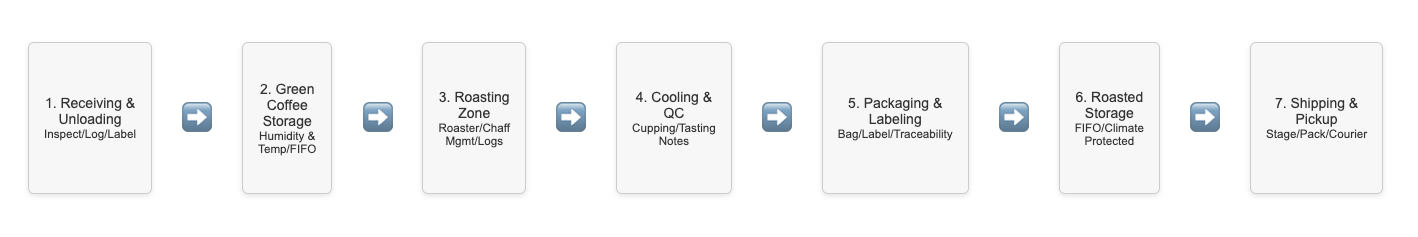

Step 2: Break Down the Core Functional Zones

Think of your roastery as a series of connected stations, each optimized for specific, repeatable tasks. The magic happens when these zones work together seamlessly.

Receiving & Unloading Green Coffee

This is where coffee enters your world, and first impressions matter—for both quality control and your back. Plan for how pallets or boxes arrive. If you're receiving 150-pound burlap bags, you need different handling equipment than if you're getting 5-pound samples.

Essential equipment includes a pallet jack for larger deliveries, a hand truck for smaller loads, and consideration for liftgate access if your delivery truck doesn't have dock-level access. Don't forget immediate labeling and tracking—incoming green lots should be identified and logged the moment they enter your space.

Green Coffee Storage

Your green coffee is an investment that needs protection. Consider humidity control, temperature stability, and pest prevention. Some roasters store by lot number, others by origin or planned roast schedule. The key is consistency and easy identification.

Vertical storage with shelving units maximizes space efficiency, while horizontal solutions like barrels or large bins work well for high-volume single origins. Whatever system you choose, make sure it's labeled clearly and allows for proper inventory rotation.

Roasting Zone

This is your command center, and everything else orbits around it. Whether you're running a Bellwether, traditional drum roaster, or fluid bed system, the roasting station needs clear safety clearances, proper ventilation access, and strategic proximity to both green storage and cooling areas.

Chaff management is critical—plan for containment and regular removal. Batch tracking systems, whether digital, clipboard-based, or barcode-driven, should be within easy reach. Your roasting zone should feel like a cockpit: everything you need is at your fingertips.

Staging & Cooling

Hot coffee needs space to breathe and time to be evaluated. Cooling trays or bins should be positioned for easy transfer from the roaster without creating traffic bottlenecks. This area often doubles as your cupping station, so plan for water access and evaluation tools.

Quality control workflows happen here—tasting, logging notes, and making decisions about whether a batch meets your standards. Keep this area organized and focused.

Packaging & Labeling

Ergonomics matter when you're bagging hundreds of pounds per week. Will you stand or sit? Both have advantages, but your setup should support good posture and efficient motion. Labeling systems—whether pre-printed stickers, thermal printers, or batch-specific labels—should be integrated into your workflow, not an afterthought.

The golden rule: roasted coffee should move directly from cooling to bagging with minimal handling and maximum efficiency.

Roasted Coffee Bean Storage

Freshness is everything, so your roasted inventory needs a FIFO (First In, First Out) system that's impossible to mess up. Whether you use bins, racks, or shelf systems, organization should make it obvious which coffee needs to ship first.

Consider climate factors—heat, light, and humidity are freshness enemies. Separate bulk storage from retail packaging, and make sure your system can scale with your volume.

Shipping & Pickup

Orders need to flow out as smoothly as green coffee flows in. Plan for packing stations with supplies within reach, staging areas for daily shipments, and easy courier access for scheduled pickups. This zone should feel like a loading dock, even if it's just a designated table by your front door.

Step 3: Human-Centric Flow

The best layouts work with human nature, not against it. Minimize cross-traffic by designing paths that don't require you to walk across the entire space multiple times to complete a single roast. Create clear pathways that serve both safety and speed, no dead zones where people can get trapped/trip over or where equipment creates blind spots.

Task grouping is crucial: organize zones so related activities happen near each other. Your roasting station should be close to both green storage and cooling. Packaging should connect easily to both cooling and roasted storage. Shipping should be adjacent to roasted coffee inventory. Think of it as connecting the dots in the most logical sequence.

Step 4: Safety & Compliance

Fire safety isn't optional—it's foundational. Ensure proper ventilation for both air quality and fire prevention. Emergency exits should be clearly marked and never blocked. Research OSHA requirements and local health and safety codes that apply to your operation.

Designate PPE stations with safety equipment easily accessible. Consider first aid supplies, fire extinguishers, and emergency contact information prominently displayed. Safety isn't just about compliance—it's about creating an environment where you and your team can work confidently.

Step 5: Design Blueprint Example

Here's how these zones might connect in a practical layout.

Receiving Area: Near the main entrance or loading door, with space for temporary staging of incoming shipments.

Green Storage: Adjacent to receiving, with clearly labeled shelving or bin systems organized by roast priority or origin.

Roasting Station: Centrally located with proper ventilation, positioned between green storage and cooling area for minimal movement.

Cooling/QC Area: Immediately adjacent to roasting station, with space for evaluation and batch logging.

Packaging Station: Connected to cooling area, with labeling supplies and packaging materials within arm's reach.

Roasted Storage: Near packaging area, organized for easy FIFO rotation and order fulfillment.

Shipping Staging: Close to exit point, with space for packed orders awaiting pickup.

The key is creating a logical flow where coffee moves in one primary direction: from green storage → roasting → cooling → packaging → roasted storage → shipping. Backtracking should be minimal and purposeful.

Common Pitfalls and How to Avoid Them

Clutter creep kills efficiency. Without systems for purging old inventory, rotating stock, or designating temporary vs. permanent storage, even the best layout becomes chaos. Build regular cleaning and organization into your routine, not just when things get desperate.

Single-person bottlenecks happen when workflows are designed around one operator. If you're planning to grow, design zones that can accommodate multiple people working simultaneously without creating safety hazards or workflow conflicts.

Storage overload occurs when you don't plan for growth. Your green coffee storage might work fine for 100 pounds, but what happens when you're ordering 500-pound lots? Build scalability into your systems from the start, even if you don't need it immediately.

Staff confusion emerges from unclear zones or missing standard operating procedures. If someone else can't walk into your roastery and understand the system, it's not sustainable. Document your workflows and make them intuitive.

Tools & Accessories to Make Life Easier

Smart tools can transform good workflows into great ones. Label printers like Zebra or Rollo models create professional-looking batch labels and inventory tags. Gravity bins or scoops standardize portioning and reduce spillage. Mobile carts let you move supplies where you need them rather than walking to fixed locations.

Airtight containers protect quality and create consistent storage. Wire shelving maximizes vertical space and stays organized better than solid shelves. QR codes can link physical batches to digital roast logs for advanced tracking.

The key is choosing tools that solve real problems, not just adding complexity for its own sake.

Final Tips for Iterating Over Time

Start with what you have, but sketch out version 2.0. Your current space might not be perfect, but you can optimize within existing constraints while planning for future improvements. Ask your team—or yourself—where the friction lives. What tasks feel clunky? Where do you waste time or motion?

Time yourself doing each major task. You might discover that your packaging process takes three times longer than it should, revealing opportunities for optimization. Your layout should evolve with your volume and goals. What works at 100 pounds per week might not work at 1,000 pounds per week.

Conclusion

A safe, intentional workflow isn't fancy, it's foundational. The most successful roasteries aren't necessarily the ones with the most expensive equipment or the largest spaces. They're the ones that have eliminated friction from their daily operations, creating environments where great coffee can be produced consistently and efficiently.

Your workflow should serve your ambition, not limit it. When every movement has purpose and every process flows logically, you're not just roasting coffee, you're building a sustainable business that can grow.

Take time to sketch your current layout or plan your ideal one. Share it with fellow roasters (like us) or mentors for feedback. The investment you make in thoughtful design will pay dividends every single day you walk into your roastery. Start with intention, iterate with experience, and remember: the best workflow is the one that works for you.